公司新闻

产品

联系嘉瑞杰

山东嘉瑞杰机械科技有限公司

联系人:王经理

电话:0531-88670722

手机 : 15866677695

地址:济南市天桥区梓东大道鑫茂科技城143号楼102室

快速成型两种加工方式区别在哪里?

来源:http://www.jrjmockup.com作者:山东嘉瑞杰机械科技有限公司发布时间:2021-09-23

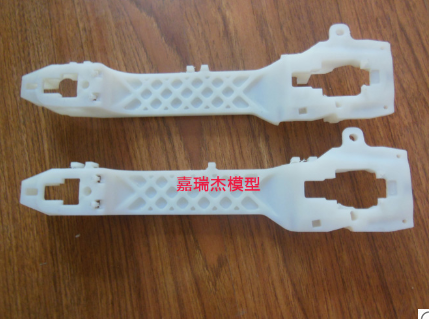

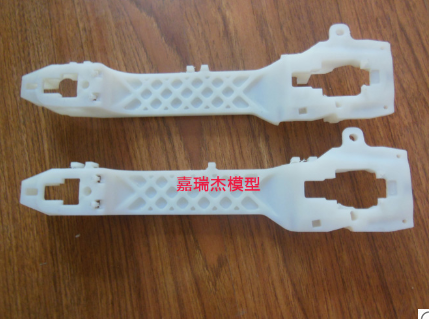

光固化快速成型系统和激光选区烧结快速成型系统是在手板模型制作应用上的主要两种加工方式。那么这两种快速成型有什么相同点和不同点呢??

Light curing rapid prototyping system and laser selective sintering rapid prototyping system are two main processing methods in the application of hand model making. So what are the similarities and differences between the two rapid prototyping??

一、两种快速成型技术的相同点

1、 Similarities between the two rapid prototyping technologies

这两种成型技术的原理都是非常相似的,另外都是作为手板模具制作用不可缺少的技术,在工业设计上也是应用的方法。

The principles of these two forming technologies are very similar. In addition, they are indispensable technologies for hand mold making, and they are also applied in industrial design.

二、两种快速成型技术的不同点

2、 Differences between two rapid prototyping technologies

光固化快速成型系统所用的材质是粉末状的物质激光选区烧结快速成型系统所采用的一种液态形状的光敏树脂,光固化快速成型系统优点在于,凡是可以溶解的所有粉末状的物质,都是可以用来制造原型或者模型的,所制造出来的产品都是可以用作产品的首样测试和结构组装件的。所以激光选区烧结法可以利用的材质非常广泛,比如说尼龙材质,比如说PC材质,比如说其他的腊粉,甚有些五金的材质都是可以做到的。

The material used in the light curing rapid prototyping system is powdery material, a liquid photosensitive resin used in the laser selective sintering rapid prototyping system. The advantage of the light curing rapid prototyping system is that all powdery substances that can be dissolved can be used to manufacture prototypes or models, The manufactured products can be used as the first sample test and structural assembly of products. Therefore, laser selective sintering can use a wide range of materials, such as nylon, PC, other wax powder, and even some hardware materials.

通过以上方式加工出来的产品,精度都是相差比较大,但是因为激光选区烧结法可以烧结很多的材质,甚有些冷门的陶瓷层都能做到,所以说激光选区烧结法工艺更加具有广泛的应用性,在行业的应用范围大,吸引力强,这些特点也能掩盖一下他精度不高的缺点,和表面粗糙,已经效率低下的问题。因为广大客户了解了这些属性之后,就可以将自己的产品在选择工艺的时候有个参考依据了。

The precision of the products processed by the above methods varies greatly, but because the laser selective sintering method can sinter a lot of materials, and even some unpopular ceramic layers, the laser selective sintering process is more widely applied, has a wide range of applications in the industry and strong attraction. These characteristics can also cover up its shortcomings of low precision, And rough surface, which has been inefficient. Because after knowing these attributes, customers can have a reference basis for their products when selecting the process.

一般是高档的工艺品,精度要求高,表面光洁度要求高的产品,适合用光固化成型快速成型,如果是一般的大型的产品,粗糙程度要求不高,相对低廉的产品,就选择光固化成型激光粉末烧结成型了。

Generally, it is a high-grade handicraft product with high precision and high surface finish requirements, which is suitable for rapid prototyping with light curing molding. If it is a general large product with low roughness requirements and relatively low price, it will choose light curing molding and laser powder sintering molding.

在工业的实际应用中结合上述两种快速成型技术的优缺点,为自己的产品增加成功的几率,以及降低公司的预算成本。这在行业竞争激烈的当下显得非常重要!

In the practical application of industry, combined with the advantages and disadvantages of the above two rapid prototyping technologies, it can increase the probability of success for its own products and reduce the budget cost of the company. This is very important in the current fierce competition in the industry!

下一篇: 济南手板模型制作的环节

相关资讯

手板制作加工时注意事项

2024-04-11手板加工如何服务好客户?

2024-04-09手板加工的过程及方式

2024-04-06快速成型的基本原理构成有哪些?

2024-02-27工业产品设计中常见手板件的制作方式

2024-02-23ABS手板模型的优势有哪些?

2024-02-21铝合金手板模型制作手法与维护

2024-02-10铝合金手板模型的氧化工艺介绍

2024-02-10汽车手板模型制作的低压灌注工艺

2024-02-06手把手教你怎么选机箱机柜定制工厂

2024-01-27